How to Start My Riding Mower Again if It Was Started Without Gas

Let's face it, you lot were simply having way too much fun listening to your favorite podcast with your headphones to discover that your backyard mower was running out of fuel, weren't you? After coming to a consummate stop, y'all add together more fuel.

Except now, your lawn mower won't start. It'southward trying to turn over if it's a rider, and you can tell its trying to work when you pull the cord on a push mower, just it just won't fire up.

Go ahead and set aside the frustration considering we're going to get you lot dorsum in business in a few minutes.

Generally, both a push lawn mower and a riding lawn mower will fail to start later on having run out of gas if either the fuel being added is stale or if in that location is air or debris trapped in the fuel lines. Dried fuel will not combust and air in the fuel lines volition not allow gas to menstruation to the carburetor.

Yous can consult the tabular array beneath for a quick set up, but if you need something a footling more information on how to do something, y'all can continue to your type of mower in the article and yous can also discover a quick video (if you lot're reading this early on after posting, so information technology'due south on its manner!) that I made the will guide you through the consequence.

| Lawn Mower Blazon | Likely Trouble | How to Ready |

|---|---|---|

| Push Lawn Mower | Newly added gasoline is stale and won't combust | Pinch off fuel line running to carburetor. Disconnect fuel line from carburetor and identify the fuel line in a jar. Remove the pinch and allow the stale fuel to bleed. Empty carburetor bowl of dried fuel. Reconnect fuel line and fill with fresh fuel. |

| Riding Backyard Mower (Backyard Tractor) | Dried Fuel Or Air Trapped in Fuel Lines | To remove dried fuel, pump out the fuel tank with a bombardment pump, disconnect the fuel line at the carburetor and blow out the tank with an air compressor or past rima oris. Be sure to drain the carburetor bowl likewise. To remove air, accident into the fuel tank by mouth or with short bursts with an air compressor. (See article for more safety details in the second section) |

Push button Mower Won't Start Later on Running Out of Gas

When I've serviced push button mowers over the last 7 years, I have found that stale fuel is a major culprit for an engine declining to run — specially if it was just running a few minutes prior and needed a refill after having run out of gas.

Gasoline is generally pretty clear but turns to a Mountain Dew color as information technology oxidizes and loses its combustible properties.

It's an honest mistake to apply upward the final bit of gas in a gas can mow the backyard, run out of gas, and reach for another gas can where y'all're not quite sure when y'all last filled information technology.

Was it this year? A few months ago? 2 years ago?!

Regular E10 gasoline will start to dethrone in as little equally a month without a fuel stabilizer and yous'll likely run across a pregnant performance decrease later three months.

Ethanol gratuitous gasoline (marine gas) will start to degrade after 3 months or then and you lot'll probably run across significant functioning loss after 4-6 months.

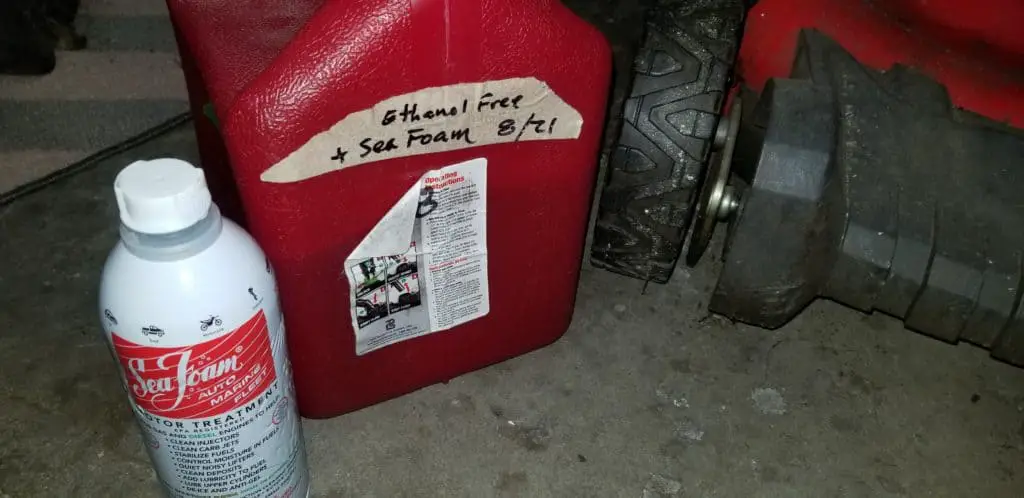

To foreclose this from ever happening again, buy yourself a bottle of SeaFoam (Amazon). You simply add together 1 fluid ounce per gallon in your gas cans, screw on the nozzle, milk shake the gas for a second, and so information technology will last for 2 years without a problem. I have personally tested this and the two year merits on the bottle is authentic.

If y'all think you've added stale fuel to your tank, but disconnect the fuel line from the carburetor and let the stale fuel drain into a jar or container. Contact your local hazardous waste materials agency and find out how to all-time dispose of it. If the fuel is less than a year old, you lot should easily be able to add together a quart or so to your motorcar on a full gas tank to dilute it an use it up.

Don't forget to drain the small amount of stale fuel in the carburetor basin as well.

In the last 7 years though, I oasis't had one push button mower that wouldn't start because of air or debris in the fuel lines. I'm not saying that information technology tin can't happen, just the fuel line from the tank to the carburetor is so short and so straight that not much can get wrong.

Still, it is possible and worth checking if you know that your engine was just running, it ran out of gas, and the new fuel is not dried.

To do this, compression off the fuel line betwixt the tank and the carburetor. Then remove the fuel line from the carburetor.

Release the pinch for simply a second to see if gas flows out of the hose. If it does, then compression it off over again.

With the hose pinched off, drain the gas (if in that location is any) from the carburetor basin from the drain spiral (if yours has one). If yours doesn't, similar mine, go ahead and remove the lesser bolt to remove the bowl. Clean any debris from the bottom of the bowl.

If you accept a lawn mower that has a carburetor that looks like the motion-picture show above (Snapper), then the side by side two steps are optional. Simply since we already accept the basin off, information technology's a skilful practice.

First take a can of carburetor spray cleaner with the minor blood-red straw that comes with it and squirt a few shots into the main tube that runs up the carburetor (encounter the flick) to articulate out any possible debris. It'll be a tight clasp and you'll have to bend the straw a footling fleck. The principal jet might be up there, or it may be the actual bolt that holds the bowl onto the carburetor (see the 2nd movie).

Secondly, since the fuel line is disconnected from the carburetor, go alee and eject a few shots of carburetor cleaner in to the connection point of the carburetor where the fuel line hooked upward (fuel inlet). The fuel should spray out the bottom of the carburetor if the float is dropped down (which it should be with the basin removed).

Some carburetors accept a minor screen in there between the float needle seat and where you connect the fuel line. If the screen got caked with debris that was floating around at the bottom of your tank and made its mode down the line with the last of the gas on your first tank, then this volition go along gas from entering the carburetor.

If that's the instance, you'll take to remove the air filter assembly and the carburetor. You lot'll then need to remove the bladder and squirt carb cleaner back through the float needle seat and accident the debris out of the fuel inlet.

Some fuel inlets tin can exist removed with vice grips by pulling and twisting to access the dirty screen as well.

At present, back to what we were doing as far equally checking gas flow.

With the gas line still pinched and the basin of the carburetor all the same off, go ahead and reconnect the fuel line to the carburetor. Release the compression for a moment and encounter if gas starts flooding out of where the carburetor basin should be.

If information technology does, that y'all know that you have fuel that is flowing properly and this isn't your problem.

Again, I haven't seen this be the issue before. In theory it's possible, but I detect that stale gas is the leading crusade of a push mower failing to offset after it has been refueled.

Riding Mower Won't Start After Running Out of Gas

Riding mowers, on the other hand, have more than of a chance from my experience of non starting due to air in the lines if you just rain out of gas and refueled.

The gas tank is often located in the back and at that place are several feet of hose that winds down to the engine. It's much easier to get an air pocket blocking things.

Again though, make sure that you don't accept stale fuel added to the tank. If you practise, either pump it out or disconnect the fuel line from the inline fuel filter and drain it out into the original gas can that had the stale fuel to begin with. Dispose of properly.

To prevent this from ever happening again, buy yourself a bottle of SeaFoam (Amazon). You but add i fluid ounce per gallon in your gas cans, screw on the nozzle, milkshake the gas for a second, and so it will last for two years without a problem. I have personally tested this and the two twelvemonth claim on the canteen is accurate.

If you know the fuel is skilful, we're going to go ahead and try to remove the trapped air in the fuel line.

Most of these backyard tractors (at least all of them that I've worked on) are non gravity fed from the tank to the carburetor. In that location is a fuel pickup tube that sticks down from the superlative of the fuel tank to virtually the lesser, and fuel is sucked up through that tube and down to the carburetor via a vacuum fuel pump that is attached to the engine.

If we get too much air in the line, the procedure won't piece of work. Information technology's simply like driving a hand-pump well down into the footing and expecting to become water when you first cycling the handle. Nothing is going to happen.

We demand to prime the pump!

A footling air will work its way out, but big gaps of air — like when you ran the tank completely empty and the hose started sucking air — will result in an engine that won't kickoff.

In that location are two easy means to do this.

The kickoff is if you don't have an air compressor.

Make certain to clothing safety glasses.

With the gas cap removed, place your rima oris upward against the gas tank (brand a seal with your face and the tank) and slowly but forcefully blow into the tank. Obviously, do not breath in through your mouth!

A friendly reminder is to slowly reduce your air pressure level going into the tank before you back your face abroad. If you blow really hard and pull your face back, you're likely going to get splashed in the face with some gas.

This will push any stubborn air bubbling down the line to where they tin eventually vent out through the carburetor.

Do this procedure until y'all see a decent amount of fuel in the fuel filter (assuming it's articulate) and then effort starting the mower again.

If you lot're not seeing any fuel make it to the filter, you can always disconnect the fuel line from the fuel filter and try blowing into the tank again. If no fuel comes out of the hose, and then information technology's likely clogged from droppings.

You can try snaking a relatively flexible wire in the fuel line to see if you tin can loosen the blockage and try blowing into the tank again.

The second method is to use an air compressor. You don't want the PSI to be besides much when doing this. Probably 20psi or and then will be fine and we'll only be using short i-2 second bursts.

You tin can either use this in place of your mouth on the gas tank by placing your paw over the gas tank fill up hole and then pushing the air compressor nozzle betwixt your thumb and index finger. Become ahead and give it a few brusk bursts with a few seconds in between.

You lot're essentially filling the gas tank with excess air, it expands, and as it tries to return to its normal volume the air will displace the liquid and strength the liquid gas up the pickup tube and down to the carburetor.

Yous tin too practise this procedure from the reverse finish of the lawn tractor. Go ahead and make sure the gas cap is securely on the tank then remove the fuel line from the fuel pump on the engine. Go ahead and do the aforementioned thing where you squirt air into the fuel line for a 2d or and so.

This volition drive air pockets back into the gas tank, and as the tank expands and pressurizes, it will displace the liquid gas and forcefulness it upwards the pickup tube and down to your terminate of the hose.

It might take a few brusk bursts, but once gas starts flowing out go alee and immediately hook information technology dorsum up to the fuel pump and try to beginning the mower.

Source: https://homebatterybank.com/how-to-start-a-push-or-riding-mower-after-it-runs-out-of-gas/